ESAB HFR (Heavy Flexible Rubber) and HOFR (Heavy Oil-Resistant Flexible Rubber) welding cables are designed for high-performance welding applications. Here are the specifications and features for both types:

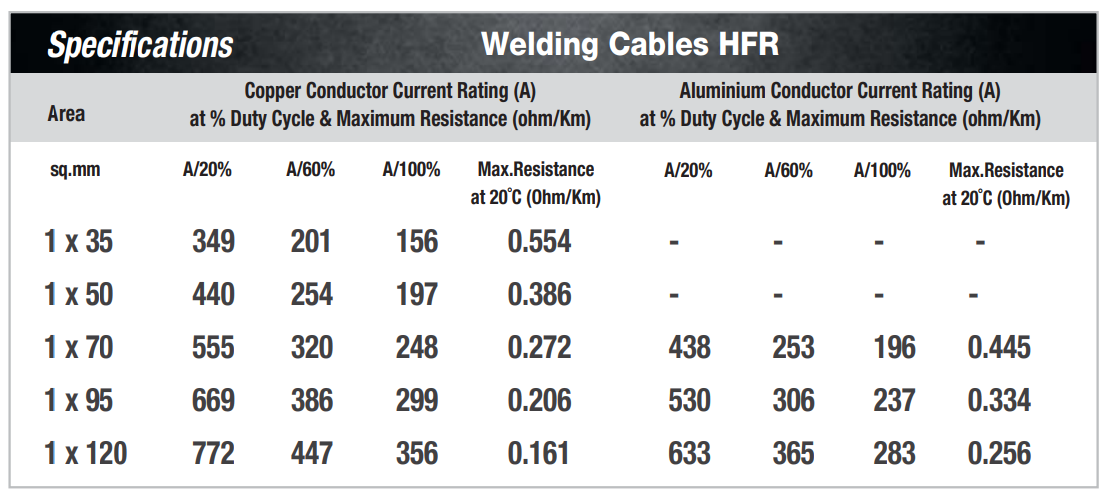

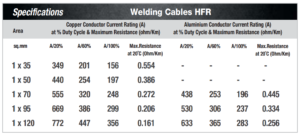

ESAB HFR Welding Cables

Specifications:

- Construction: Made with heavy-duty flexible rubber, designed for durability and flexibility.

- Temperature Range: Typically rated for up to 90°C.

- Insulation: Highly flexible rubber insulation for easy handling and movement.

- Voltage Rating: Often rated for 600V, suitable for various welding applications.

- Current Carrying Capacity: Depending on the cable size (mm²), usually ranges from 70A to 600A.

- Applications: Suitable for MIG, TIG, and MMA welding processes.

Features:

- Flexibility: Designed for easy maneuverability and use in tight spaces.

- Durability: Resistant to abrasion, cuts, and mechanical stress.

- Safety: High insulation resistance, ensuring safety during use.

- Temperature Resistance: Designed to withstand temperatures up to 90°C.

- Insulation: Excellent insulation properties ensure safety and durability.

- Copper Wires: Made from high purity electrolytic grade copper, minimizing resistance losses.

- Performance: Delivers consistent voltage and amperage, even with varying lead lengths.

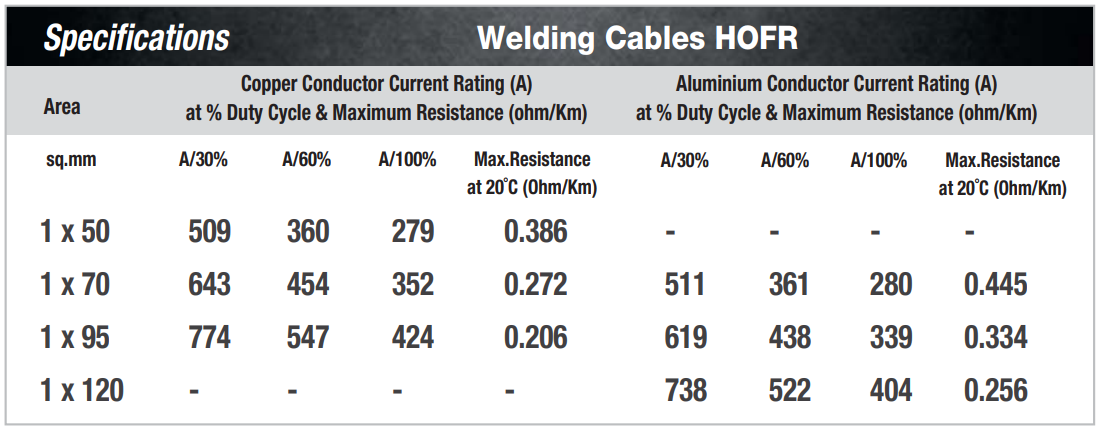

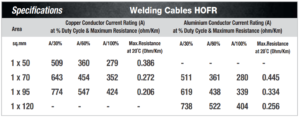

ESAB HOFR Welding Cables

Specifications:

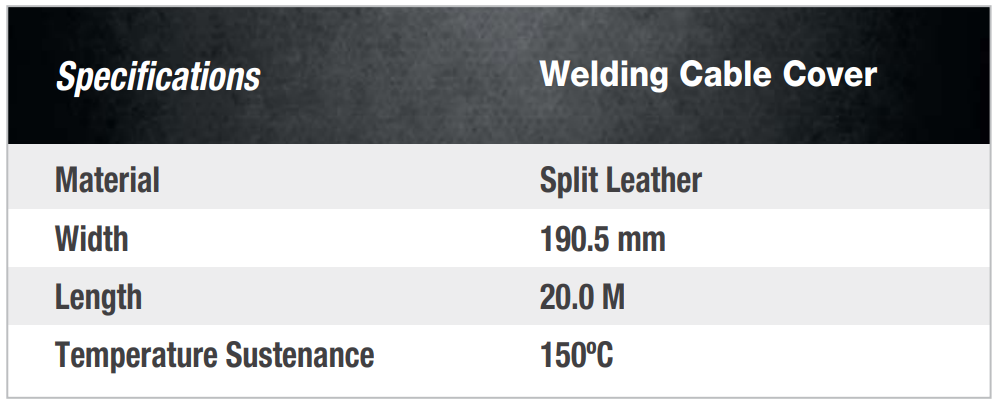

- Construction: Made with oil-resistant flexible rubber, ideal for harsh environments.

- Temperature Range: Typically rated for up to 120°C.

- Insulation: Heavy-duty rubber insulation, resistant to oil and chemicals.

- Voltage Rating: Often rated for 600V, suitable for various welding applications.

- Current Carrying Capacity: Depending on the cable size (mm²), usually ranges from 70A to 600A.

- Applications: Ideal for use in environments where oil exposure is common, suitable for MIG, TIG, and MMA welding.

Features:

- Oil Resistance: Specially formulated to withstand exposure to oils and chemicals.

- Flexibility: Maintains flexibility even in low temperatures.

- Durability: Designed to resist abrasion and mechanical wear, ensuring a long lifespan.

- Temperature Resistance: Capable of withstanding temperatures up to 120°C.

- Insulation: Provides the same excellent insulation and safety features as HFR cables.

- Copper Wires: Also made from high purity electrolytic grade copper for minimal resistance.

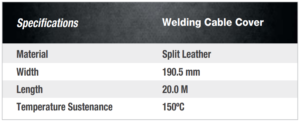

General Information:

- Available Sizes: HFR and HOFR cables are available in various cross-sectional areas (mm²), catering to different current requirements.

- Standards Compliance: Often comply with relevant international standards for safety and performance.

- Energy Efficiency: Reduces power losses during operation, enhancing overall efficiency.

- Durability: Built to withstand harsh working conditions, ensuring longevity.

- Safety: Flame retardant properties increase safety during use, especially in demanding environments.

Usage:

Both HFR and HOFR welding cables are suitable for professional and industrial applications, providing reliable performance in demanding environments.

Reviews

There are no reviews yet.